Reduce your inventory cost to a minimum. Extended supplier collaboration and accurate forecasting minimises purchase costs and lead time, eradicates costly buffer stock and improves cash flow.

IMPROVE CUSTOMER SERVICE WITH SMART DEMAND, SUPPLY AND DISTRIBUTION REQUIREMENTS PLANNING

- ERADICATE BUFFER STOCK

- IMPROVE CASH FLOW AND REDUCE INVENTORY COST

- IMPROVE CUSTOMER EXPERIENCE

- OPTIMIZE STOCK LEVELS

SUPPLY CHAIN MANAGEMENT FUNCTIONALITIES

Achieve the lowest possible inventory cost

Extended supplier collaboration and accurate forecasting minimizes purchase costs and lead time, eradicates costly buffer stock and improves cash flow.

Delight customers, every time

Smart demand, supply and distribution requirements planning improves customer service with optimized available-to-promise and stock levels

Benefits

- Improve customer experience

- Reduce inventory cost

- Improve cash flow

- Eradicate buffer stock

Purchasing management

Automate and streamline purchasing processes including invoice/order matching, purchase suggestions, purchase order (PO) accruals, PO limits and approval workflows, quality assurance controls, RFQ generation, supplier agreement integration, and supplier sourcing rules to increase efficiency, minimize errors, drive down costs and improving customer service.

Distribution requirement planning (DRP)

Analyse expected/actual demand and available stock level in future periods to identify future expected replenishment needs to meet a requested minimum stock level.

Purchase order processing

Automate and streamline the fundamental purchasing processes critical to success through a configurable and intuitive workflow engine.

Web supplier delivery schedules and planning

Share forecast information with suppliers using EDI standards ANSI, EDIFACT, BISAC and ONIX to inform production planning and reduce inventory and costs across the supply chain. Manage gross or net supplier (or vendor) managed inventory (SMI), or advanced information forecast processes.

Pricing management

Manage the impact of price with streamlined modelling. Define standard purchase and sales prices to be applied upon any item. Define pricing exceptions depending on criteria, where items might receive a different base purchase/sales price than the one defined as standard.

Catch weight

Manage goods weighed during reception and/or picking, manipulating the price unit quantity instead of calculating using a conversion factor. An extension of price unit functionality that allows the manual changing of price unit quantity/quantities for a sales/purchase order line down to each individual order line quantity during reception confirmation, purchase order entry, pick list confirmation and sales order entry.

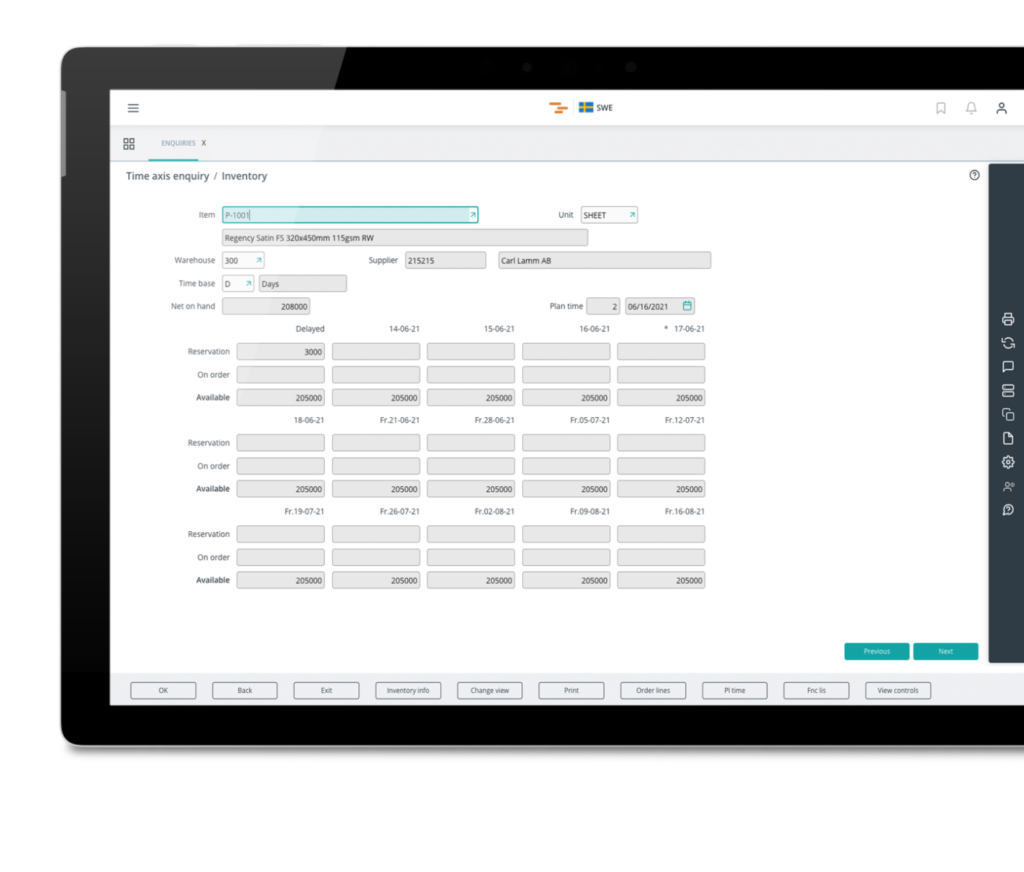

Inventory control

Reduce stock and increase turnover with sophisticated inventory analysis that provides visibility of stock volume, value and movability, seasonal trends, inventory turnover, lead times, and deviations in plans. While proactive replenishment suggestions and simulation functionality forecasts and automates the most appropriate stock levels, order timing and economic order quantities (EOQ).

Supplier marketing support

Manage joint marketing programs, checking margins, managing rebates. Reduce associated administration by automatically applying marketing agreements and tags to product lines, calculating rebates and communicating with payment software, discount application, sales planning, quotes, orders and invoices, and margin calculation including supplier rebate/chargeback.

Supplier rebates and returns

Protect the bottom line by quickly, accurately and automatically tracking and invoicing rebates, with dynamic rebate functionality for different regions and industries, rebate statistics, claim management, accrual to financials, and claim creation through A/R and A/P.

Contract managed inventory (CMI)

Manage externally owned stock in the warehouse(s) which is sold via inventory contracts such as customer deposit stock (CDS), supplier consignment stock (SCS), or own stock in a business partner(s) warehouses which you can purchase via inventory contracts and then sell, such as wholesaler consignment stock (WCS), wholesaler deposit stock (WDS). Plus customer/wholesaler buffer stock and (C/WBS) and deferred indent stock (DIS). CMI functionality automatically ensures terms and conditions, compliance and accountabilities are adhered to across the most complex warehouse systems.

Landed cost handling

Gain visibility and control of landed costs down to the single item level to handle shipments to port of destination including, freight, insurance, customs and taxes incurred. Identify standing liabilities, track regulatory compliance, manage purchase orders according to exchange rates, automatically process goods awaiting cost checks, and calculate import duty based on net purchase price plus any additional costs incurred.

Delight the customer at every touchpoint

Improve customer service with first class marketing, fulfilment, after-sales support and returns handling processes.

Demand visibility drives supply chain efficiency

Plan purchasing and delivery requirements on accurate customer forecasts to drive down inventory costs and increase margins.

Benefits

- Deliver first-class service

- Reduce inventory cost

- Create profitable customers

- Improve loyalty and retention

Sales management

Rich functionality controls every process and sub-process that drives the sales department. Starting with intelligent order entry and leading though a seamless chain of automated, auditable processes including cash, commission, currency, discount and credit management; gross profit control and profit check; lost sales tracking; order structure, configuration, summary and settlement; sales order allocation, delivery and invoicing; order scheduling, surcharge, price and tax handling; sourcing policy management; vendor managed inventory.

Customer rebates

Make sure customers are only ever charged the right price, with a fully automated, accurate, integrated rebate capability that saves administration expenses, reduces costly errors, enables margin control and keeps track of expected rebates. Functionality includes dynamic rebates for different regions and industries, rebate statistics, profit and margin calculations, generation and maintenance of payments, and accrual to Financials.

Automated requests and returns

Keep customers happy, even when there’s a problem, with automated complaints handling for an easy, fast and smooth customer experience. Including alerts of returns and approval to send a replacement or do repairs; providing customer service personnel with detailed information; automating all actions and paperwork; calculating percentage refunds; tracking product through end-to-end process back to supplier; initiating recalls and monitoring their return if part of a batch; making staff aware if a product is put back on the shelf; and reporting on trends in order to continually improve quality levels.

Product configuration

Give your customers choice and respond quickly to requests while maintaining control of the supply flow. Create one-off products from standard parts without having to add new products, but maintaining the ability to, if required. Set rules on product assembly and parts, enabling products to be built using these combinations to suit customers’ needs, automatically testing different options, generating quotes, and calculating cost price and item or customer margins. If an order is placed order structures can be created for warehouse personal to gather and package the different products in stock. If production is required then BOM (bill of materials), BOR (bill of routing), operation lists and pricing are automatically created.

Customer portal

Give customers flexible self-service access to credit status, invoice status, payment and order entry.

Customer Delivery Schedules

Integrate with customers to provide better service. Reduce inventory and costs by planning purchasing and delivery based on customer forecasts shared as customer delivery schedules via industry standard data formats such as ANSI and EDIFACT. Customer delivery schedules support vendor managed inventory (VMI), receiving customers’ gross forecasts with sales statistics, stock on hand, and min-max inventory levels to calculate and automatically create orders to ensure customers are replenished. Net forecasts are also received via the standard data formats and handled automatically. Inventory management is continually tracked and analysed, calculating lead times and delivery dates, with any mismatch triggering warnings to enable the proactive management of issues.

Customer relationship management (CRM)

A holistic view of the customer, throughout the marketing, sales and service cycle with a complete suite of tools to grow more profitable customer relationships. Enabling customer analysis to identify customer types and build appropriate marketing plans to target them more effectively, and creating sales and marketing budgets that can be turned in to demand forecasts. Deliver high levels of customer experience with a 360-degree view of the customer across functions, a seamless and precise fulfilment and after sales process, extensive quotation handling, automated multi-channel sales order processing, available-to-promise with dynamic sourcing options, and customer self-service online, 24/7.

Matrix handling

Effectively manage items with common and varying characteristics (e.g. clothing). Select and group items into an item matrix and effectively integrate purchasing, inventory, sales and item management across the supply chain, expediting the entry of sales and purchase order lines for items that belong to an item matrix, while improving customer service and cost control. Matrix functionality allows applicable quantities of matrix items to be entered quickly and easily during ordering, rather than one-by-one. Sales pricing can also be established to price matrix items in any way, using normal pricing techniques, or special item matrix pricing (quantity dependent) for individual item lines or the entire matrix, meaning that the accumulated quantity for all item combinations within the matrix is used to retrieve the sales price for the sales order lines created.

Mobile sales

On demand tools to close deals, anywhere, with access to catalogs, sales order creation and customer records.

The flexibility to support any value-add activity

Meet shifting market demands for value added services with the efficient, accurate and reliable operational control to adapt your assembly and/or manufacturing business processes.

Complete control of manufacturing & assembly

Comprehensive functionality designed for the supply chain environment, where flow-oriented and demand driven manufacturing meets customer requirements.

Benefits

- Reduce lead times

- Increase delivery reliability

- Improve customer service

- Add more value

Production scheduling

Provides multiple planning methods to fit requirements. For repetitive manufacturing shortage analysis and/or priority analysis methods of pull planning can be used. MRPII is also supported, with order proposals prioritised down to lowest component level, to forecast on fulfilling demand in the right order.

Manufacturing alternative products (co-Products)

Accommodates alternative products, or co-products, in response to orders. Alternative products are defined in the manufacturing structure file as possible items to be produced, as a specified percentage or quantity that can be produced as an alternative product. The manufacturing reception function is used to define whether the product is the planned end-product or an alternative that should be received to stock.

Manufacturing orders

Multiple order creation methods for flexible set-up and performance

- Manufacturing order entry: orders can be entered manually, copied from existing orders, initiated by and connected to a customer order, or released from an order proposal.

- Manufacturing order proposals: MRP order proposals are automatically generated at the requirements planning stage, and can be easily modified or cancelled. When pull-planning is used, order proposals correspond to the material shortage and priority analysis.

- Lead-time calculation/availability check: lead time calculation and availability checks allow sales order availability to be secured even when production lead-times are changing

- Operational planning: perform forward or backwards operational planning and connect material operations to minimize WIP costs for materials used later in production. Group manufacturing orders both on header and an operation level to reduce set-up cost (time), extending machine availability, optimizing resources and minimizing waste.

- Manufacturing order documents: can be tailored by order type, including operation list, pick list, operation cards, material cards, assembly report, material list / operation, and product labels.

- Track and trace batch number: track and trace products in batches by automatically generating batch numbers, at point of manufacturing order creation or product reception, according to number series or using masks.

- Reserving batches and booking material: reserve batch-controlled products before a pick list is printed or reserve batches for the included material in manufacturing order maintenance for the BOM.

- Kitting list generation and re-creation: ensures the kitting list allocation remains until the order is closed. Material is re-allocated when the kitting list is refreshed, in case components were unavailable at original allocation time.

- Manufacturing order pallet handling: create pallets at shop floor (document print and report on pallet), or at manufacturing order reception with associated pallet labels, enabling pallet identity to be used when reporting products to stock.

Graphical planner view

Information is presented via a graphical planning interface through which updates can be performed, including refresh pull-planning proposal; change proposal; create order (manufacturing and/or purchase order); change manufacturing order quantity, start/completion date, order priority/sequence; open a closed manufacturing order; change manufacturing order operation priority, sequence or work center; print manufacturing order operation cards; reschedule operation; reset operation; manufacturing operation reporting; manufacturing order reception; change work center capacity; and change proposal.

Preventive maintenance and service integration

A fully integrated solution for proactive internal maintenance and preventive service on machines (work centers) and tools that connects service objects to work centers or tools. Proactively reduce the capacity for works centers when planning preventative service and automatically create service orders when a tool that is being calibrated reaches its calibration point.

Rough-cut disposal check on Material and Capacity at Order Entry

Checks against normal stock and adjusts for exceptions, calculating ‘best delivery date’ if stock/capacity is not available within the item’s planning timeline.

Tools and fixtures

Plan better with auto allocation of tools for manufacturing order operations. Including the ability to calibrate a tool when it has been used for a specified number of orders, produced pieces or hours.

Subcontract operations

Support external production within internal processes by defining operations as subcontract, creating a purchase order and connecting it to the manufacturing order from the subcontract operations.

Internal order replenishment (stock requests)

Visibility of stock across distribution centers and the ability to create internal replenishment orders, rather than ordering stock from a supplier, increases group inventory turns. All intercompany accounting is handled via internal purchase orders and internal sales orders.

Manufacture order reporting

Multiple reporting options such as PC, workshop terminals or bar code readers and shop floor reporting including used, produced and scrapped quantities, reason codes, person-time used, machine resources and other cost elements. Automatically ‘un-book’ allocated materials and/or operations, whereby pre-calculated values will be used. WIP can be analyzed online including material, time used and other costs to uncover deviations between pre-calculated and actual values and take appropriate action.

- Backflushing: backflush materials with a number of setup options, including backflushing material at operation reporting, with materials connected to a specific operation being issued from stock at completion of the operation, or backflushing at product reception, with materials being issued from stock at the same time that the manufactured products are reported to stock. Roll-back of backflushing routines not accepted at the final reporting step is also included.

- Operations reporting: calculate the run labor time and machine time based on reported quantity (approved and scrapped), or approved and scrapped quantity, with calculations defined at the work center level. Alternatively choose no calculation. Operations reporting also supports milestone reporting, automatically updating previously completed operations in a process

- Manufacturing order material allocations: facilitates status handling on materials, allowing open and close of manufacturing order material reservations for not fully issued components.

Quality control

Obtain quality control reports during the manufacturing process, at manufacturing reception or for stock items. Quality reporting set-up is based on conformity groupings connected to one or many products, with criteria used to define the values to be used for reporting different processes, such as manufacturing operation reporting. Results are stored in a history file, and can be queried for analysis. Non-conformity certificates are created for quantity reported, for example outside a defined criteria or value.

Closed manufacturing order analysis: analyze completed manufacturing orders providing visibility of those with high deviation. Re-open orders to perform reporting adjustments, with the possibility to adjust reported values.

Manufacturing order block order handling

A ‘contract’ or ‘repetitive manufacturing flow’ that enables the creation of daily, weekly or monthly manufacturing orders with some default values, as well as the ability to create simple reception reports with backflushing for both material and operations.

Activity oriented product costing

Flexible and efficient cost control and follow-up is performed with a wide spectrum of options to fit different manufacturing environments. Compute variations of material, machines and labour overheads with cost price simulation functionality. Use alternative manufacturing routes or bills of material while still achieving accurate product cost calculation and follow-up. Enter any element of a cost calculation either manually, by individual algorithm, or from cost tables. ‘What if’ analysis is reported performing cost simulations on-line, and entry and calculations for extremely low-cost products is possible, as is the ability to base calculations on standard quantities for product costing on produced items for better accuracy. Saved current and previous product costs and simulations include total bill of materials (BOM), bill of routing (BOR) and overview presentation, for greater visibility of how it was constructed. BOM/BOR (quantities and times) can be updated from actual manufacturing order statistics (average values), and there is a detailed audit trail to track all BOM/BOR changes.

Visibility, control and fastest ROI on the market

The distribution chains to today have changed beyond recognition from those of just a few years ago. Now it is the large, sophisticated, 24-hour, lights-out DC that is becoming commonplace across industries. Such centers require advanced information technology and flexible software systems, from companies that understand distribution, in order to run. That software is Iptor’s WMS solution, formerly known as IBS Dynaman, the world’s most advanced software application suite for Distribution and Wholesale operations.

Robust warehouse processes and operations

Iptor’s wms is a key part of the supply chain that controls the movement and storage of materials within a warehouse and processes the associated transactions, including shipping, receiving, put-away, and picking. Iptor’s Warehouse Management solution also directs and optimizes stock put-away based on real-time information about the status of bin utilization. It includes best-of-breed WMS and MES functionalities based on the latest Microsoft technology. Scalable, functional, easy-to-use, and simple to implement, Iptor’s WMS represents the lowest total cost of ownership and fastest ROI in the industry – guaranteed.

Benefits

- Reduce inventory

- Reduce labor costs

- Increase storage capacity

- Increase inventory accuracy

Complete process control

ensures strict process control, accurate data capturing and complete visibility across manufacturing and distribution boundaries.

Value-added activities

including inline services, such as customer labeling or perishable goods handling, or offline services, such as kitting, build-to-order and assembly.

Advanced functionality

addresses multi-owner, multi-site, dock and yard management, cross-docking, cartonization, labor management, multi-level container handling, returns and more.

Operational transparency

provides real-time, dashboard visibility across the organization, from vendor managed inventory and built-to-order, to supply-in-line sequence, reverse logistics and more.

Flexible rules engine

ensures your processes fit your business, from how materials flow to how workflows are applied in specific instances.

Integrated labor management

transforms how you measure, manage and motivate your workforce to improve productivity, utilization and engagement.

Mobile Service is an engineer/technician management application which is accessible via a browser on mobile devices. In Mobile Service an engineer can retrieve and manage all service jobs assigned to him which are grouped and ordered on service job list. It gives engineer access to the standard service job handling processes available in

DC1

- Service parts adding

- Checklist verification

- Time reporting

- Object reporting

Benefits

- Real time, remote connectivity meaning

- Easier track and trace of workload for remote service engineers

- Complete visibility of parts consumed during service jobs

- Reduced administration

- Increased accuracy of information gathered

- Increase worker productivity

- Improved processing times

- Extend existing applications to mobile workers

- Increase employee and business partner responsiveness and decisions

- Moves paper-based processes to handheld devices

- Uses all common browsers to ensure complete compatibility